Planning and Assembly for Light Art Project

I was asked to plan and manage the electrical assembly, testing, and packing of a 60-piece artwork for artist Leo Villareal for Brown University.

Planned

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut Labore et dolore magna aliqua. Id leo in vitae turpis. Arcu cursus vitae congue mauris. Risus at ultrices mi tempus imperdiet. Scelerisque felis imperdiet proin fermentum leo vel orci. Velit euismod in pellentesque massa placerat duis. Enim nunc faucibus a pellentesque sit amet porttitor eget. Volutpat blandit aliquam etiam erat velit scelerisque in.

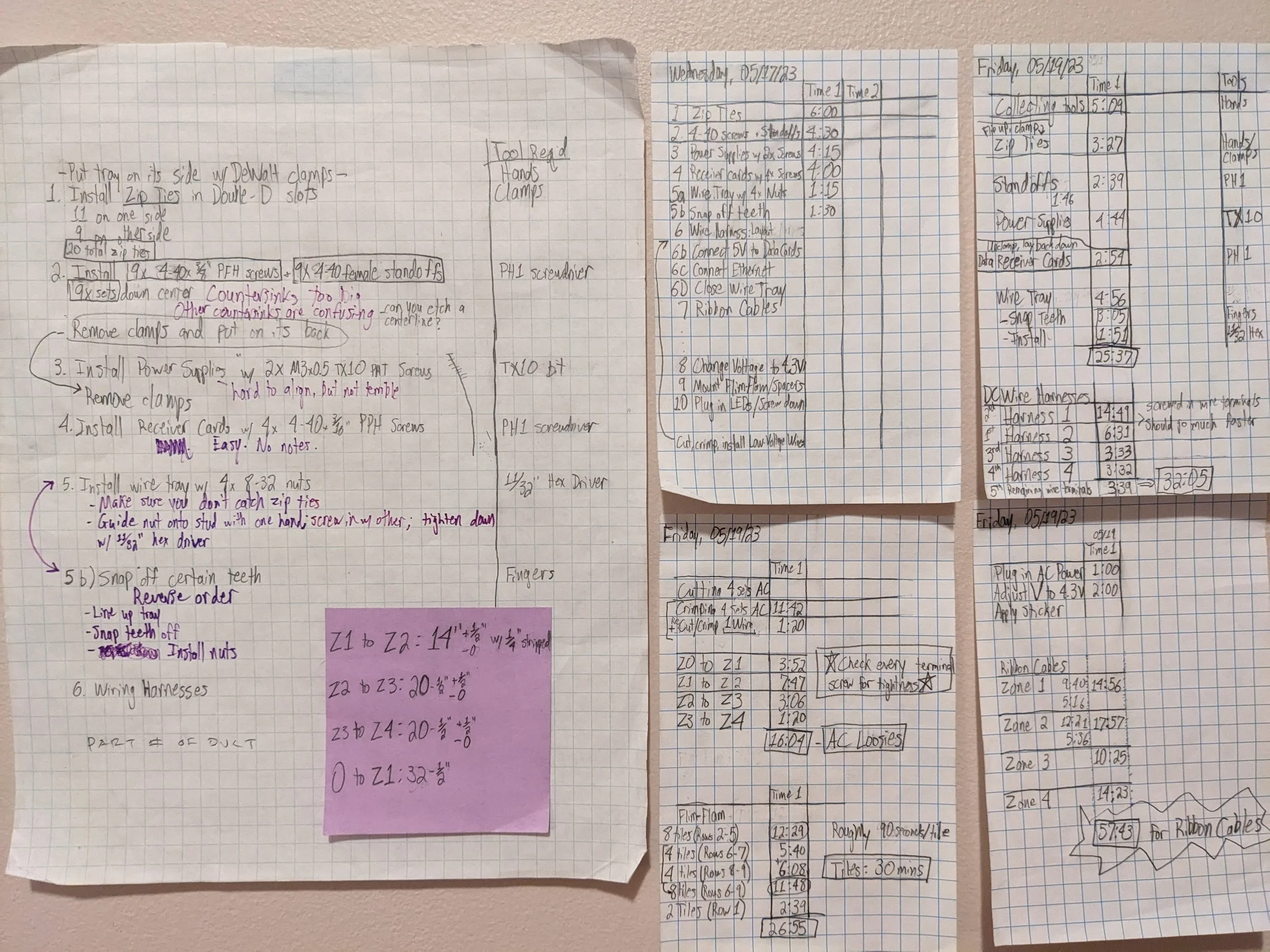

Tracking and timing each operation to plan for ideal staffing for completion goal of four assemblies per eight-hour day

Order of Operations sheet posted on each wall for easy reference

Comparing Staffing (1 Person/Board vs 2 People/Board) vs Time after completing prototypes

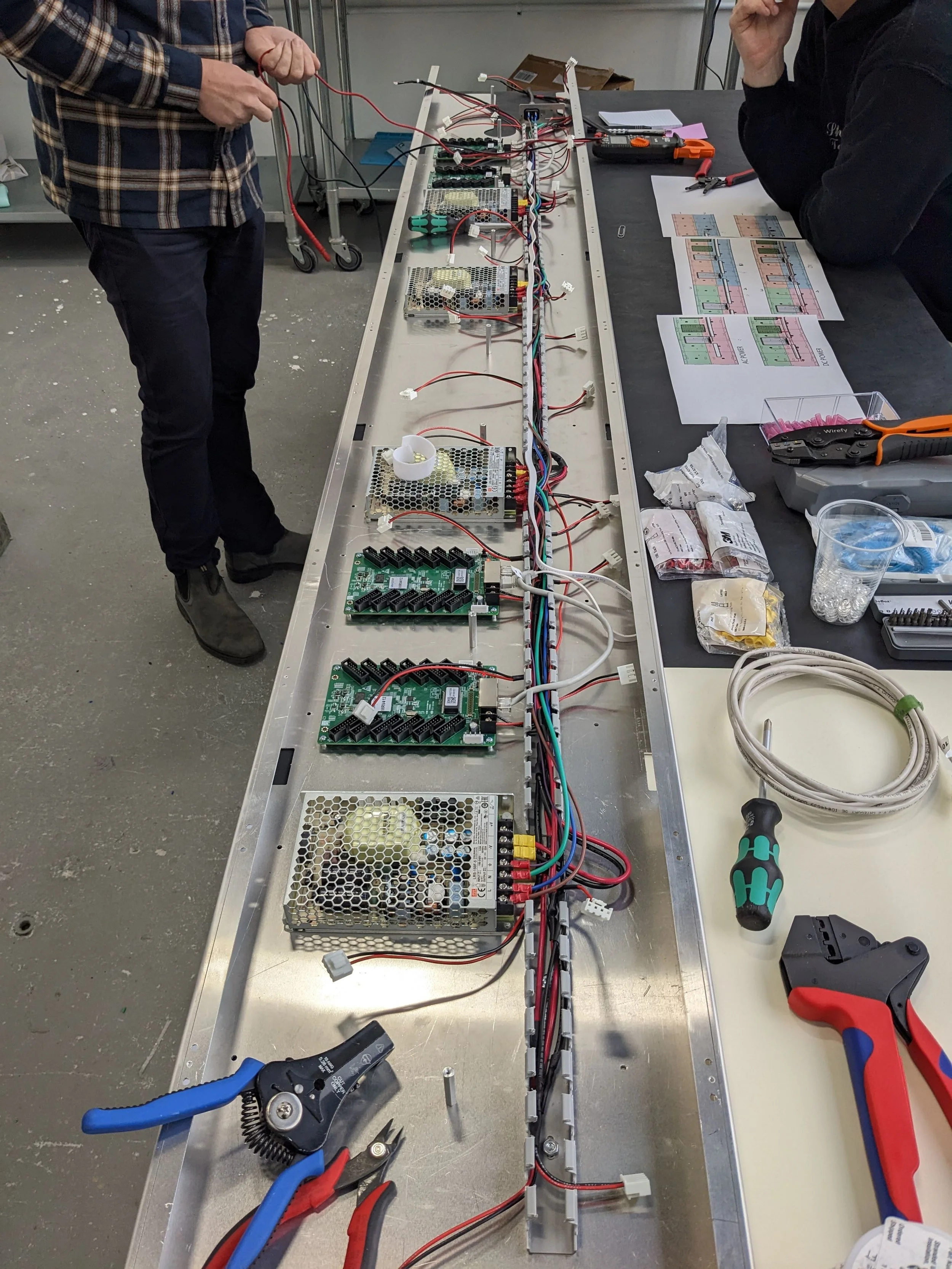

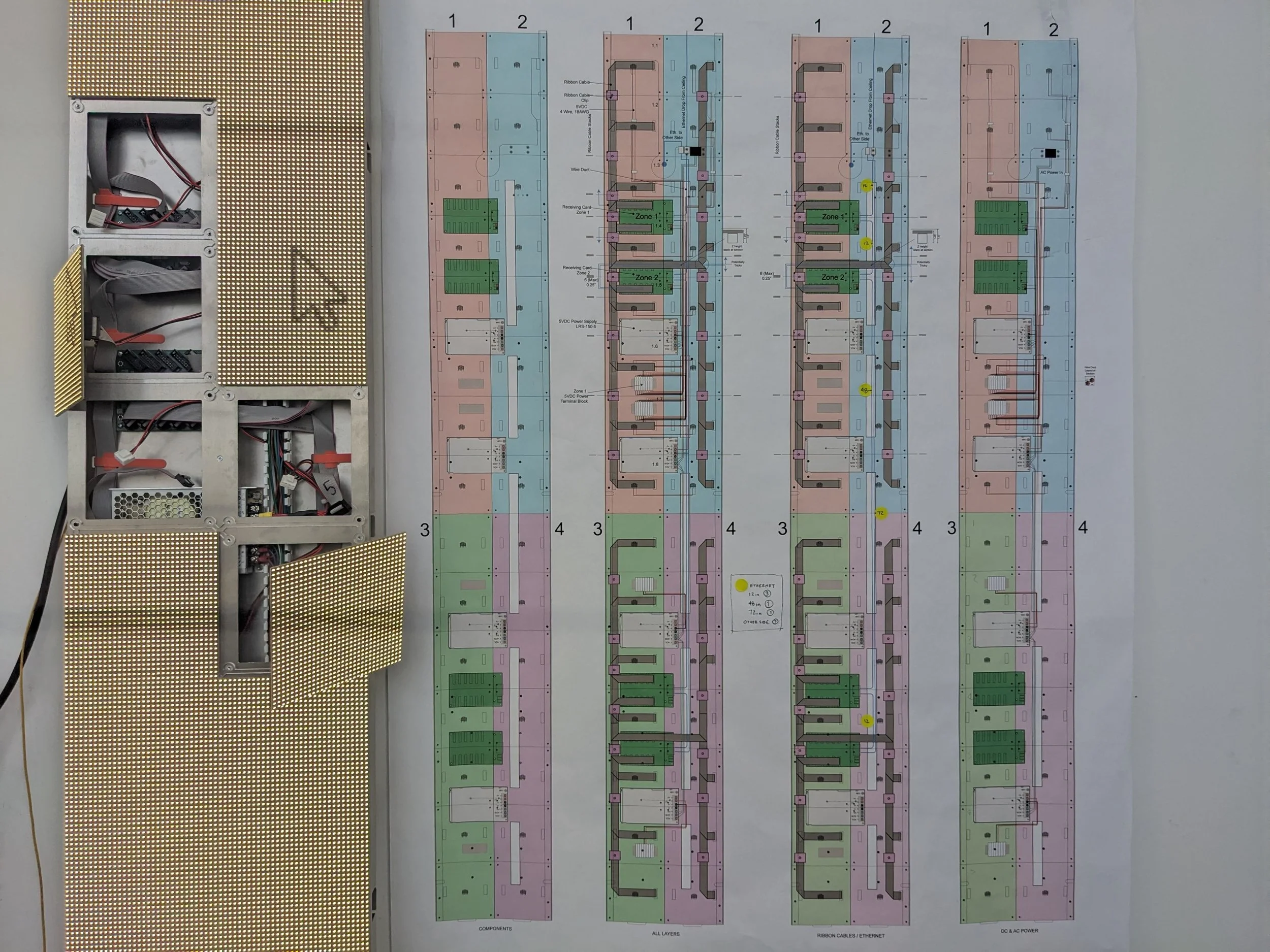

Partial assembly with Power Supplies, Data Receiver Cards (green), Low-Voltage Wiring Harness and Ethernet cables, and plastic Wire Duct

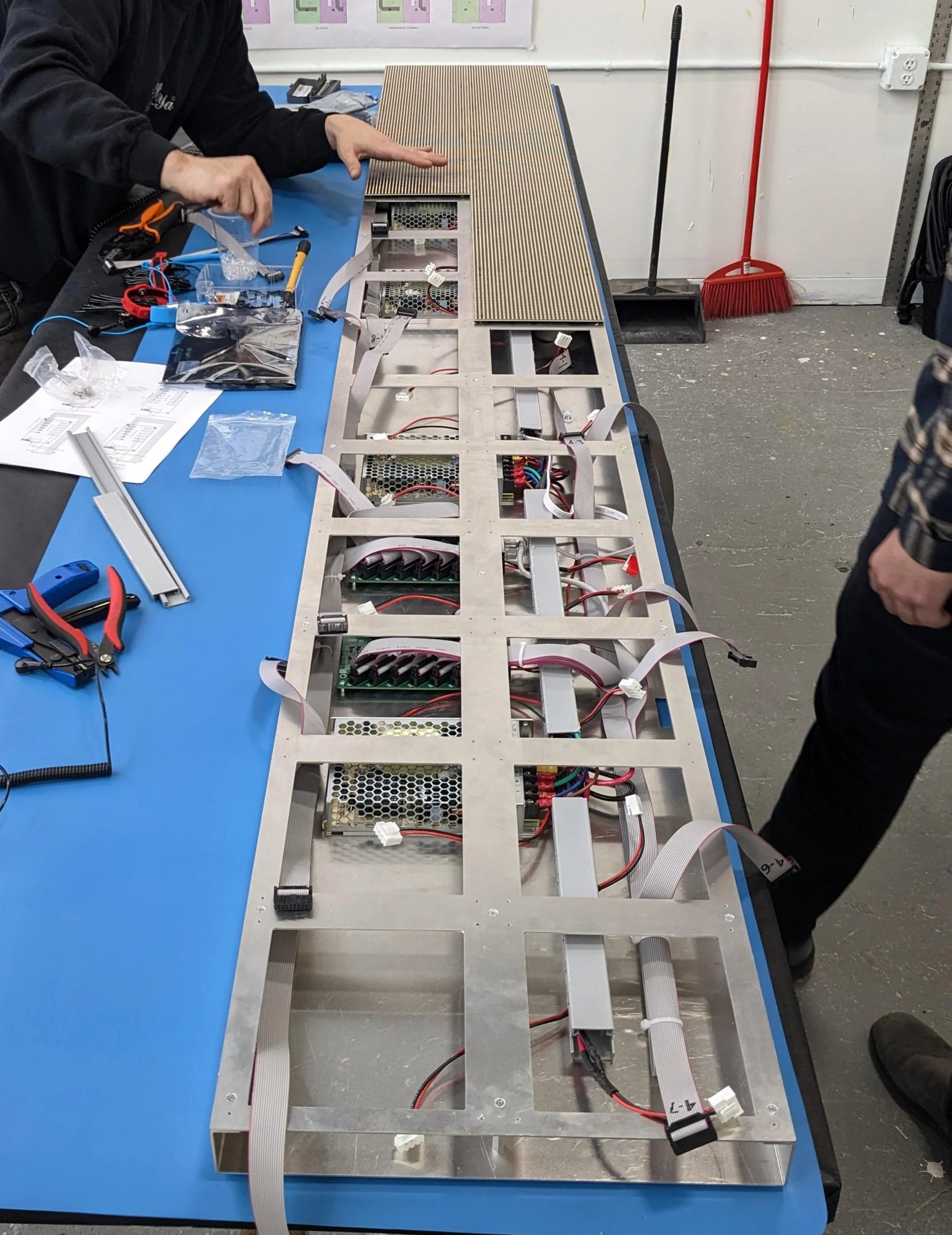

Assembly with aluminum Cover Plate screwed into standoffs. Cover Plate has riv-nuts to accept each LED Tile's screws. Ribbon Cables (gray) and Low-Voltage plugs (white) poke through each hole, waiting for their LED Tiles.

LED Tiles screwed onto assembly. There were custom laser-cut acrylic spacers to prevent interference between the LED Tiles and electrical components beneath.

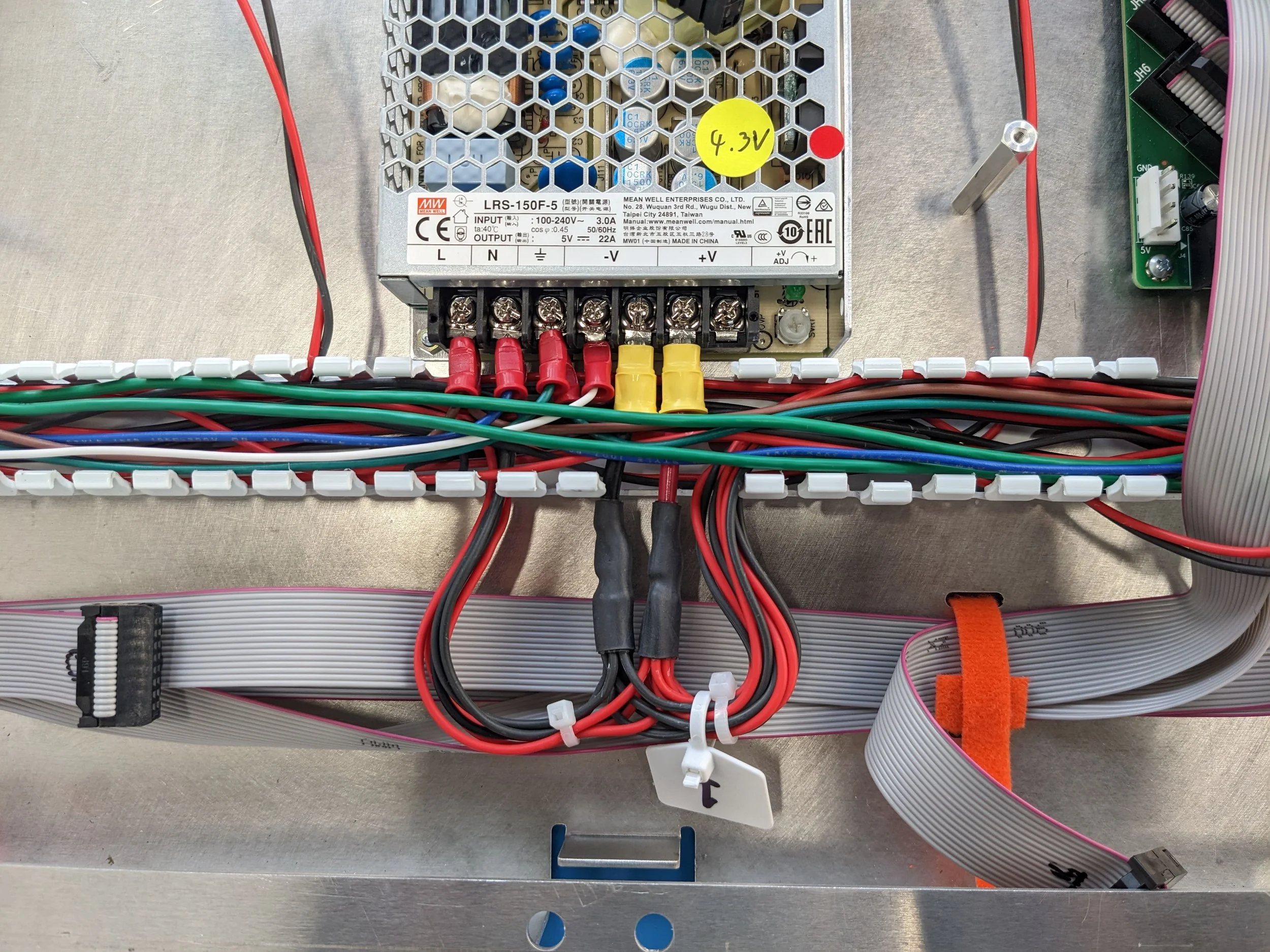

Close-up view of one of four Power Supplies with tidy cables. The Power Supply steps down voltage from 120V to 4.3V to power the LED tiles and Data Cards. Power and Ethernet cables were daisy-chained between Power Supplies and Data Cards.

Completed assembly displaying the mouse pointer from the attached computer in all four quadrants

Partially disassembled board

Completed Assembly (with some Tiles removed to reveal wiring underneath) juxtaposed against original wiring diagram.

Packed assemblies awaiting pickup